Now Reading: Isambard Manufacturing Scores $9M to Revolutionize UK Critical Production with AI

-

01

Isambard Manufacturing Scores $9M to Revolutionize UK Critical Production with AI

Isambard Manufacturing Scores $9M to Revolutionize UK Critical Production with AI

Table of Contents

Bringing Manufacturing Home: Isambard Lands $9M to Rebuild UK Critical Industries with AI Smarts

Hey everyone, gather ’round because we’ve got some exciting news brewing in the UK tech scene! Ever worry about where crucial components – think parts for defence, aerospace, or even medical devices – actually get made? For decades, a lot of that manufacturing has drifted overseas, leaving Western economies vulnerable when global supply chains get shaky (as we’ve seen plenty of recently!). But what if we could bring that production back, making it smarter, faster, and more resilient right here? That’s exactly the mission of a bold British startup called Isambard, and they’ve just landed a cool $9 million (£7 million) in seed funding to make it happen. This isn’t just another funding story; it’s about leveraging cutting-edge tech like AI to tackle a massive challenge – the future of Isambard manufacturing and potentially, the industrial backbone of the UK and its allies.

The Elephant in the Room: Why Manufacturing Got Vulnerable

Let’s be real for a second. For years, the mantra was “offshoring.” Companies moved production to places with lower labour costs to save money. It made sense on paper, and consumers often benefited from lower prices. But it came at a cost. Manufacturing capacity and crucial skills dwindled in places like the UK. Fast forward to the pandemic, geopolitical tensions, and shipping nightmares – suddenly, relying on complex, far-flung supply chains for critical parts started looking incredibly risky.

Imagine needing a high-precision component for a defence system or a vital medical device, only to face massive delays or find the production lines are thousands of miles away in a region facing instability. That’s the problem Isambard is laser-focused on solving. There’s a huge predicted investment (£650 billion over three years, according to one source!) planned by British companies looking to reshore production, but a gap exists between this demand and the current domestic capacity. That gap doesn’t just impact business; it touches on national security and economic sovereignty.

Enter Isambard: AI-Powered Manufacturing for a New Era

This is where Isambard steps onto the stage, armed with fresh funding and a big vision. Founded in London in 2024 by the ambitious Alex Fitzgerald, Isambard isn’t just another factory. They’re building a network of manufacturing capabilities powered by sophisticated software. The recent $9M (£7M) seed round was led by Notion Capital, with significant backing from the UK Government’s National Security Strategic Investment Fund (NSSIF – previously NSIIF) and the German Federal Government, alongside other funds like 201 Ventures, Basis Capital, Forward Fund, Material Ventures, Neverlift Ventures, and NP-Hard Ventures. That lineup tells you something – this isn’t just seen as a commercial opportunity, but one of strategic importance.

So, what’s their secret sauce? It revolves around their proprietary software platform called “MasonOS.”

Decoding MasonOS: The Brains Behind Isambard Manufacturing

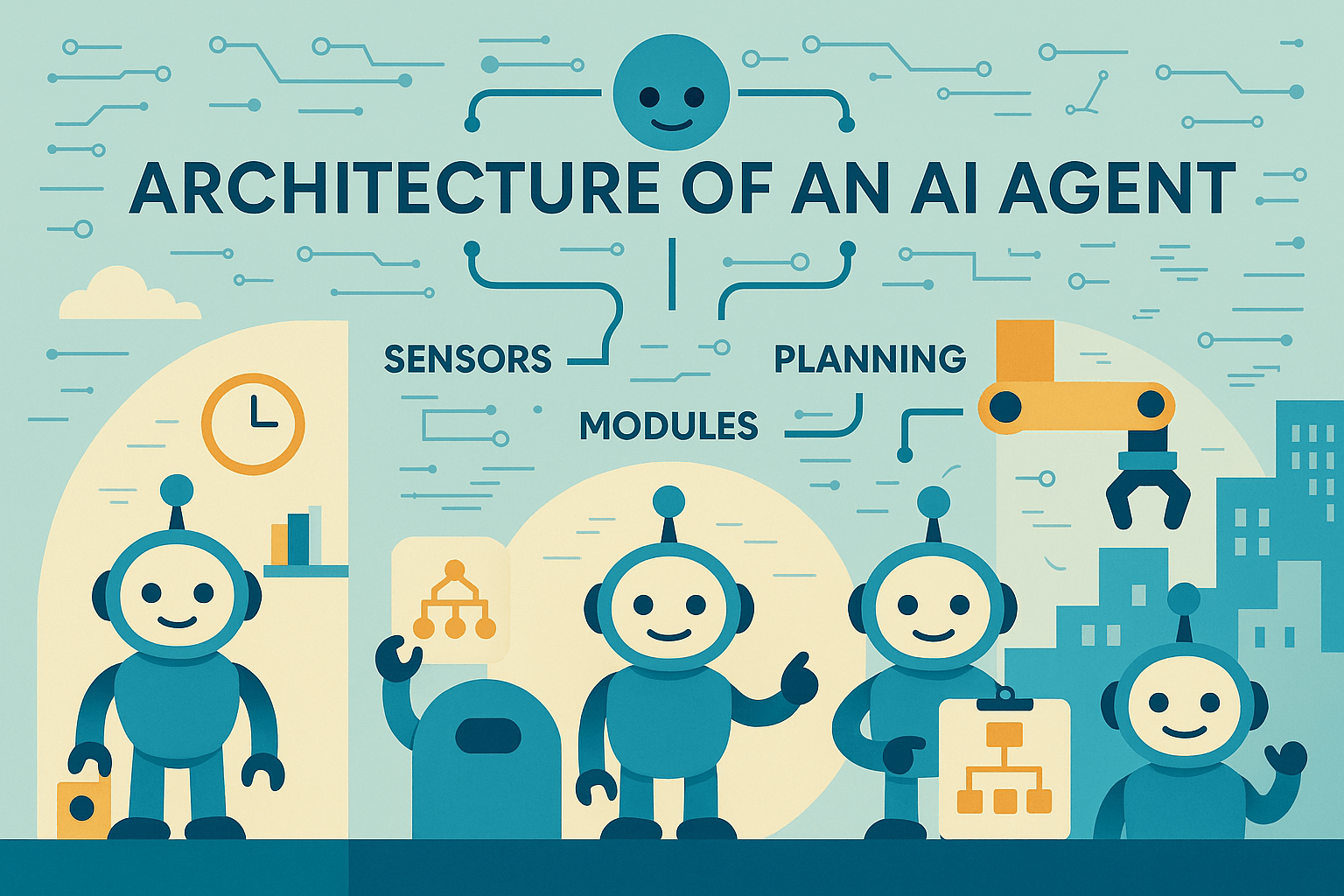

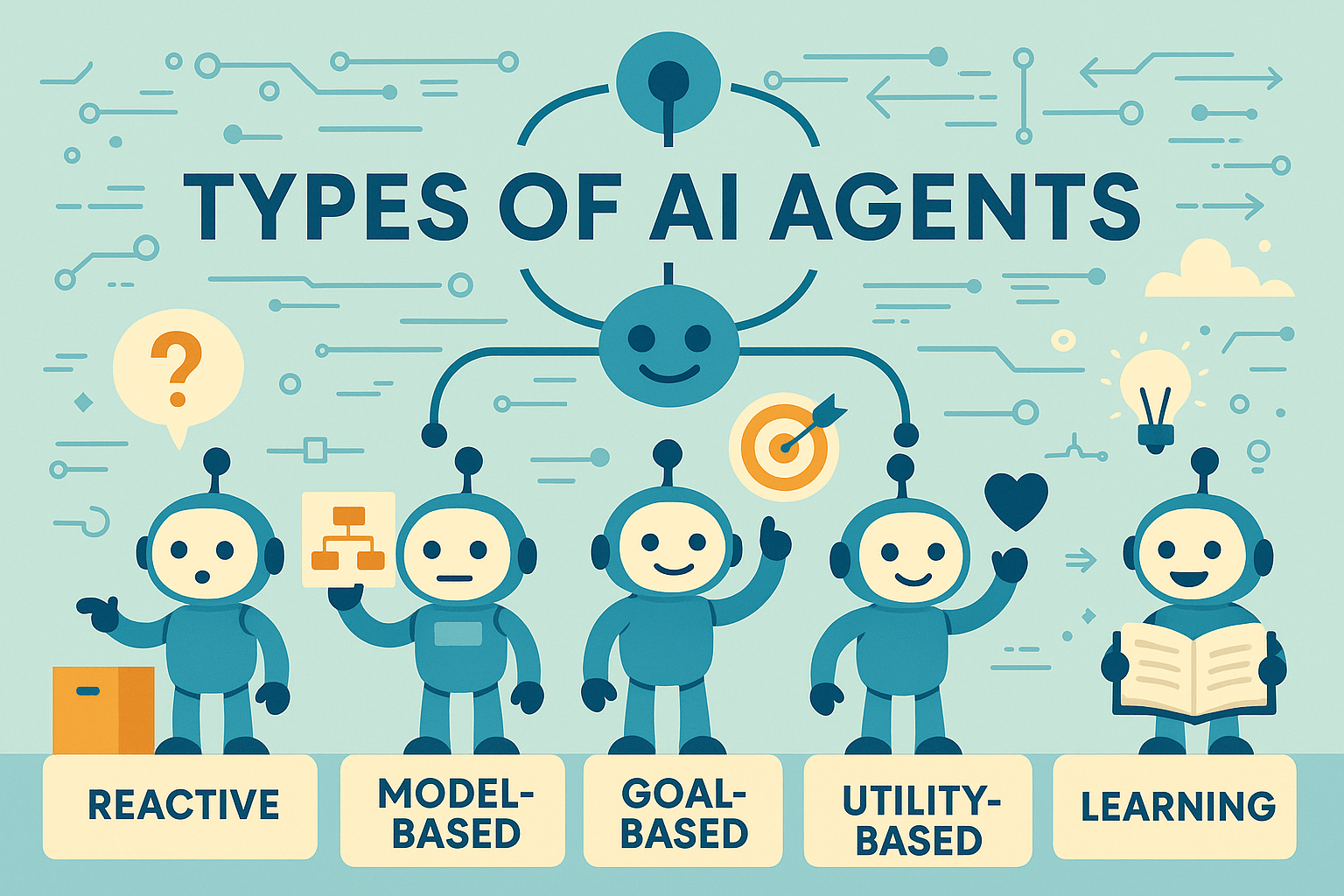

Think of MasonOS as the central nervous system for a new kind of factory. Isambard is pioneering a network of modular, highly automated manufacturing units. These aren’t giant, sprawling old-school plants. Instead, picture smaller, high-tech machine shops, potentially distributed across the country (or even internationally). MasonOS is the software that ties it all together, integrating everything from:

- AI-Driven Planning: Optimizing production schedules, resource allocation, and workflows for maximum efficiency.

- Robotics Integration: Seamlessly managing automated machinery like advanced CNC (Computer Numerical Control) machines.

- Quoting & Supply Chain: Streamlining the process from initial customer request to managing materials.

- Quality Control: Implementing real-time monitoring and potentially AI-powered checks to ensure high precision.

- Billing & Management: Handling the administrative side efficiently.

The goal is to use software to make local manufacturing not just possible again, but better – faster, more reliable, potentially greener, and more cost-effective than relying solely on traditional, often overseas, methods. Isambard is already working with fast-growing European defence and autonomy startups, proving they can deliver high-precision products quickly and with robust quality assurance.

Why Reshoring is More Than Just a Buzzword

The push for “reshoring” or “friend-shoring” (bringing manufacturing back domestically or to allied nations) is a major global trend. It’s driven by:

- Supply Chain Resilience: Reducing dependency on single points of failure in faraway places.

- Geopolitical Stability: Ensuring access to critical goods regardless of international politics.

- Quality Control: Having production closer allows for tighter oversight and faster iteration.

- Speed to Market: Shorter supply lines mean quicker delivery times.

- Intellectual Property Protection: Keeping sensitive designs and processes more secure.

- Economic Rebalancing: Rebuilding domestic industrial capability and creating skilled jobs.

Isambard’s model taps directly into this zeitgeist. As founder Alex Fitzgerald put it, “Manufacturing is the backbone of economic prosperity, national security and our collective purpose as humanity. Yet our industrial base is dying. We’re building a new model… With support from top investors who share our vision, we are forging industrial acceleration for the West.”

A Thriving UK Tech Ecosystem

Isambard’s success in securing this funding highlights the vibrancy and ambition within the UK’s technology startup landscape. It’s not just about fintech or consumer apps; British companies are tackling deep, complex industrial challenges and attracting significant investment to do so. We see this pattern across various sectors – for instance, look at how companies are innovating in traditionally complex fields like insurance. A great example is the journey of Marshmallow Insurance Startup Secures $90M, Hits $2B Valuation Serving UK Migrants, showcasing how tech-driven approaches can disrupt established industries and achieve impressive scale right here in the UK. Isambard is adding another exciting chapter to this story, focusing on the physical world of manufacturing.

For those interested in the broader push to bolster UK supply chains, the Reshoring UK initiative offers resources connecting manufacturers with accredited domestic suppliers, further underscoring the national focus on this area.

Scaling Up: What’s Next for Isambard?

With $9 million in the bank, Isambard has ambitious plans. The funding will be used to:

- Expand its First Factory: Their prototype facility, opened in London’s Zone 3 just this February (2025), serves as the testbed. Expect it to grow.

- Grow the Engineering Team: Building out MasonOS and the hardware integration requires top talent.

- Scale the Technology Platform: Refining the software and preparing it for wider deployment.

- Reach More Customers: Providing defence, aerospace, energy, and other critical sectors with their faster, more reliable production capabilities.

Interestingly, Isambard is also exploring a franchise model. The idea is to empower entrepreneurs to run their own high-tech, Isambard-powered machine shops, leveraging the MasonOS platform, national contracts, and support, while renting equipment and hiring locally. This could rapidly scale their network, creating hundreds or even thousands of these AI-optimised manufacturing nodes across the UK, Europe, and North America. It’s a distributed, scalable vision for the future of making things.

Final Thoughts: A Glimmer of Industrial Renaissance?

Isambard’s $9M funding round is more than just numbers on a page. It represents a significant bet on the power of software, AI, and automation to revitalize critical manufacturing in the UK and beyond. By tackling the challenges of efficiency, cost, and resilience head-on, Isambard manufacturing aims to reverse decades of offshoring trends for the components that matter most.

Their approach – blending advanced software with a distributed, potentially franchised network of automated production units – is innovative and timely. It addresses clear market needs and aligns with major geopolitical shifts favouring secure, domestic supply chains. Keep an eye on Isambard; they might just be forging a key part of the UK’s industrial future.